-

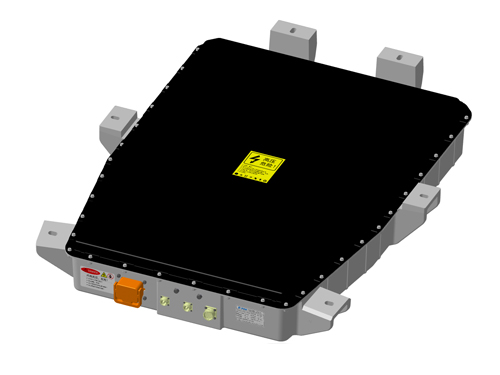

RT02 Platform

RT02 platform is developed as a track dedicated platform. This platform adopts distributed structure (BCU & BMU), and the BCU (battery control unit) is responsible for the real-time processing of data from BMU, and controlling the data of exchange and process of TCU, IDU and Ground charger. The BMU (battery measurement unit) collects data.

E-mail:nancy.zhao@hzepower.com

RT02 Platform

Distributed Structure:

Battery Control Unit (BCU) Size: 320*258.2*45 mm

Battery Measurement Unit (BMU) Size: 361.6*235*45 mm

Installation space requirement, including outlet line position:

a.Battery Control Unit (BCU) Size: 320*260 mm

b.Battery Measurement Unit (BMU) Size: 362*235 mm

Product Application:

1. Electric Vehicle:Rail transit

2.lithium battery power battery system

3. Battery types: LMO、LFP、NCM 、LTO

With the development of rail transportation technology and battery technology, the battery is used as a power system or energy storage system in the field of rail transportation, and has made great progress. RT02 platform is developed as a track dedicated platform.

The battery management system (BMS) adopts distributed structure, and the BCU (battery control unit) is as the system assembly to control and management of the core unit, and is responsible for the real-time processing of data from the battery measurement unit, and matching hardware to signal acquisition, analysis and processing, and manage the intranet CAN-bus network. At the same time, the control unit is responsible for controlling the data of exchange and process of TCU, IDU and Ground charger. The BMU (battery measurement unit) is mainly responsible for collecting single cell voltage data and collecting the battery box temperature data.

1. BMS self-checking

2. Single cell voltage detection

3. Single cell temperature detection

4. Passive balanced

5. Battery pack working current detection

6. Total voltage detection of battery pack

7. Battery pack SOC estimation

8. Battery pack SOH estimation

9. Battery pack SOF estimation

10. High voltage power supply & power off management

11. Communication with CAN-bus equipment of vehicle equipment

12. 485 Communication

13. 4-20mA Interface

14. Battery safety charge management

15. Data recording and reading

16. Delayed to turn off power management

17. 110V signal detection port

18. 110V signal output port

19. Digital signal input

| Electrical performance | Min value | Standard value | Max Value | Remark | ||

| Environment | Working temperature(℃) | -40 | 85 | |||

| Relative humidity(%) | 5 | 95 | ||||

| Pressure | 86 | 106 | ||||

| Power supply | BCU | Working range (V) | 18 | 24 | 32 | Compatible 110V |

| Work power consumption (W) | 3 | 4 | ||||

| Sleep power consumption(W) | 0.5 | 0.75 | ||||

| BMU | Working range (V) | 18 | 24 | 32 | Compatible 110V | |

| Work power consumption (W) | 4 | 5 | ||||

| Current detection | Current detection range(A) | / | 1000 | / |

According to sensor parameters |

|

| Current detection accuracy (%) | / | 1% | 2% | |||

| Current detection sampling period (mS) | 5 | 10 | ||||

| Total voltage detection | voltage detection range(V) | / | 1000 | / | According to sensor parameters | |

| Detection accuracy (%) | / | 1% | 2% | |||

| Voltage detection sampling period (mS) | 5 | 10 | ||||

| Single cell voltage detection | voltage detection range(V) | 0 | 5 | |||

| Detection accuracy(%.FSR) | ±0.2 | ±0.5 | ||||

| Voltage detection sampling period (mS) | 20 | 100 | ||||

| Temperature detection | Temperature detection channel number | 8 | ||||

| Detection range (℃) | -40 | 125 | ||||

| Detection accuracy (℃) | ±0.5 | ±1 | ±2 | |||

| Sampling period (mS) | 500 | 1000 | ||||

| Withstand Voltage Grade(W) | 3100VAC | |||||

| Protection Grade | IP54 | |||||

Rail Transit System

Rail Transit System

Rail Transit System

Rail Transit System

Rail Transit System

Rail Transit System

Rail Transit System

Rail Transit System

Rail Transit System

Rail Transit System

Rail Transit System

Rail Transit System

Inquire:RT02 Platform

- *Contact:

- *Phone:

- Company:

- Mailbox:

- *Msg:

-

*Code:

Related products

- EV Power Battery System of Electric Logistics vehicle(II)

- Rated voltage(V): 265 (Customized) Rated battery pack capacity (Ah): 94 (Customized) Rated battery pack energy (KWh): 24.9 (Customized) Voltage range (V): 202-302 (Customized) Max. Charge current (A): 270 (Customized) Max. Discharge current (A): 94 (Customized) Cycle life (time): >3000 (80% DOD) BMS working voltage ( Vdc): 12 SOC estimation accuracy: <5%~8% Temperature difference: <=8°C Thermal management: Natural heat dissipation Applications: EV, Logistics vehicle

- EV Power Battery System of Electric Bus

- With the electrification of urban traffic, new energy commercial vehicles, especially new energy buses, have been rapidly applied. Provide a battery management system is stable and reliable and assembly services for electronic billion of new energy vehicle customers, effectively improve the vehicle mileage, life cycle, guarantee the high safety of the vehicle.

- EV Power Battery System of Electric Logistics vehicle(I)

- Rated voltage(V): 328.5 (Customized) Rated battery pack capacity (Ah): 99 (Customized) Rated battery pack energy (KWh): 32.5 (Customized) Voltage range (V): 252-378 (Customized) Max. Charge current (A): 290(Customized) Max. Discharge current (A): 100 (Customized) Cycle life (time): >1000 (80% DOD) BMS working voltage ( Vdc): 12 SOC estimation accuracy: <5%~8% Temperature difference: <=8°C Thermal management: Natural heat dissipation Applications: EV, Logistics vehicle

Contact E-POWER

Tel:+86-0752-2629948

Add:No.40 Huifeng east 2nd road Zhongkai High-tech district Huizhou, Guangdong, China .